Since the David Brown Corporation had bought the Tickford Coachbuilding Works in Newport Pagnell during late 1954, the production of the bodies of the DB2/4 Mark II was moved entirely to the historic factory and away from Mulliners in Birmingham who were responsible for the coachwork of the DB2/4. Within a few short years, AML would move completely from Feltham and make it’s new home in the historic Buckinghamshire town.

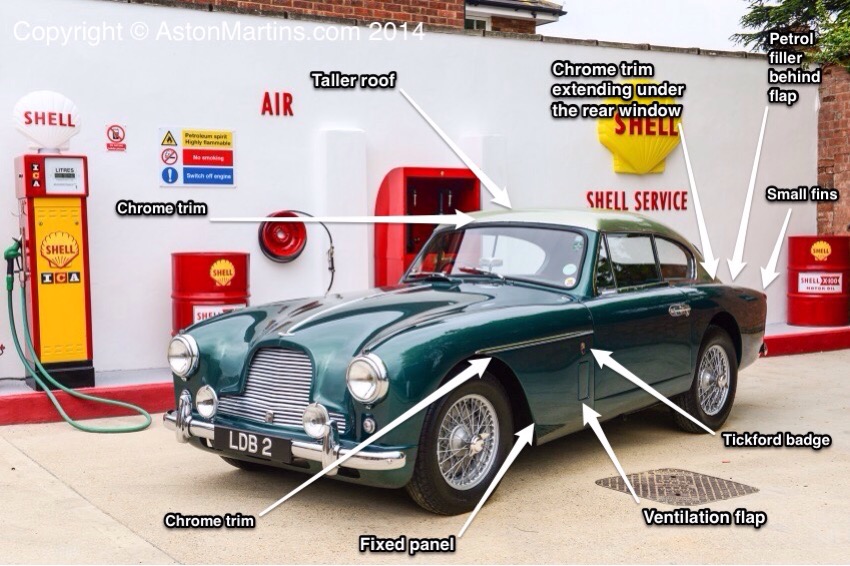

Externally, the roof line was raised to give better headroom so a chrome strip extends from the top of the windscreen wrapping around to above the side windows. Although the strip looks a bit clumsy, it allowed the Mark II to continue to use the same windscreen as the drop .head.The strip joins with trim along the edge of the roof, sweeping down the side window extending both around the bottom of the rear window and the side glass. With all these chrome strips, it is hardly surprising that a fair few DB2/4 Mark II’s also had fashionable two tone paint finishes. More noticeable are the vestigial tail fins which were thought of as stylish in the 50’s. The dainty bubble type taillights were taken from the contemporary Hillman Minx.

An easy way to differentiate the Mark II from the previous DB2/4 is that she side panels of the bonnet remains fixed to the chassis when the bonnet is raised. This was done in the interests of simplicity ditching a costly aluminium casting and reducing the weight of the opening bonnet. The spilt line is clearly visible by a chrome strips separating the two pieces of the body. Maybe this was also the very beginning of what became the signature Aston Martin side strake as first seen in the DB4.

Initially, the 140 bhp engine was the same as fitted to the later examples of the DB2/4 model (VB6J), but as an optional extra, the Special Series engine (VB6J/…../L or L1) could be fitted. The Special Series engine had 165 bhp on tap which was achieved by the fitting of larger valves and high lift camshafts. More power would also be further specified by optional 40 DCO Weber carburettors to replace the SU’s, high compression pistons, an integral oil cooler and twin exhausts